In recent years, additive manufacturing has been making headlines left and right. You may have even heard some people refer to it as 3D printing in conversation.

If you have a background in engineering or design, you will have likely heard of this emerging technology and design method. But not everyone is familiar with additive manufacturing and 3D printing. That’s why we’ve put together this simple guide to additive manufacturing.

In this article, we will break down what is additive manufacturing, and why it’s a durable solution for many industries.

Overview of What Is Additive Manufacturing

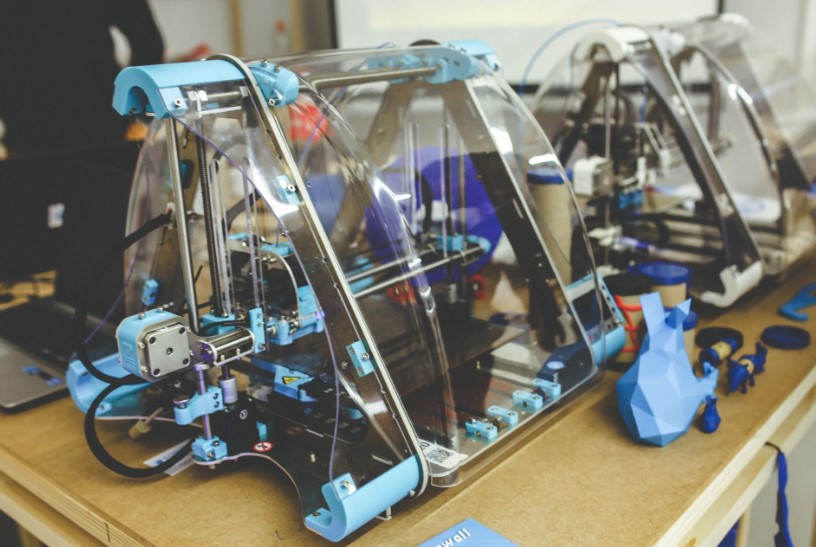

Additive Manufacturing (AM) is the process of making three-dimensional solid objects. This is done out of a digital file. It is also known as 3D Printing.

The process begins with the creation of a three-dimensional digital model of the object. This model is then used to generate a two-dimensional cross-sectional pattern. These patterns are then used to create successive layers of the object until it is complete.

AM has been used to create everything from simple objects like cups and plates. It is also used for complex objects like medical implants and aerospace parts. Technology is constantly evolving and becoming more widely available.

Many believe that AM will revolutionize manufacturing. It can also eventually lead to the mass production of customized products.

Benefits of Additive Manufacturing

There are many benefits of additive manufacturing. Perhaps the most obvious is that it allows for the creation of products that would otherwise be impossible to create using traditional manufacturing methods. Additive manufacturing also offers a lot of flexibility when it comes to design.

It also can create customized products. Additionally, additive manufacturing can be faster and less expensive than traditional manufacturing methods. AM also often results in less waste.

By layering materials to create products from digital models, additive manufacturing has the potential to:

- reduce waste

- save time and money

- create new products

- customize products

If you want to learn more about additive manufacturing and how it can benefit your business, contact a 3D printing service or click here for more.

How the Additive Manufacturing Process is Done

In additive manufacturing, successive layers of material are laid down in different shapes to create three-dimensional objects. Each successive layer bonds to the previous one until the object is complete. In general, additive manufacturing involves three main processes:

- material deposition

- material curing

- material removal

During material deposition, a machine deposits successive layers of powdered metals, plastics, or other materials. The material is deposited layer by layer until the desired shape is created. The deposition process can be done using different methods, such as:

- stereolithography

- selective laser sintering

- binder jetting

After the desired shape is created, the next step is material curing. Curing involves using heat, light, or chemicals to solidify the deposited material. This step is necessary to give the object its shape and strength.

The last step is material removal. This step is necessary to remove any excess material that was not used in the curing process. Material removal can be done using different methods, such as machining or sandblasting.

Understanding What Is Additive Manufacturing

With the constantly evolving technology, it’s important to keep up with the different ways you can create and manufacture products. Additive Manufacturing is a process that has been growing in popularity. It’s important to understand what is additive manufacturing and the basics of how it works.

Luckily, many online resources can help explain the process and how it can benefit your business.

For more articles aside from this simple additive manufacturing guide, visit our blog page.